In today’s fast-paced manufacturing and woodworking industries, efficiency and precision are paramount. Businesses are constantly seeking reliable equipment to optimize production while ensuring high-quality results. One of the most valuable tools in this space is the industrial CNC router table. These machines have revolutionized the way materials such as wood, plastic, and metal are cut, shaped, and engraved. Among the top contenders in this category are ATC CNC routers and the Panther Series CNC routers, known for their power, efficiency, and accuracy.

In this article, we’ll explore the capabilities of industrial CNC router tables, the advantages of ATC CNC routers, and why the Panther Series CNC routers stand out as a preferred choice for many professionals.

What is an Industrial CNC Router Table?

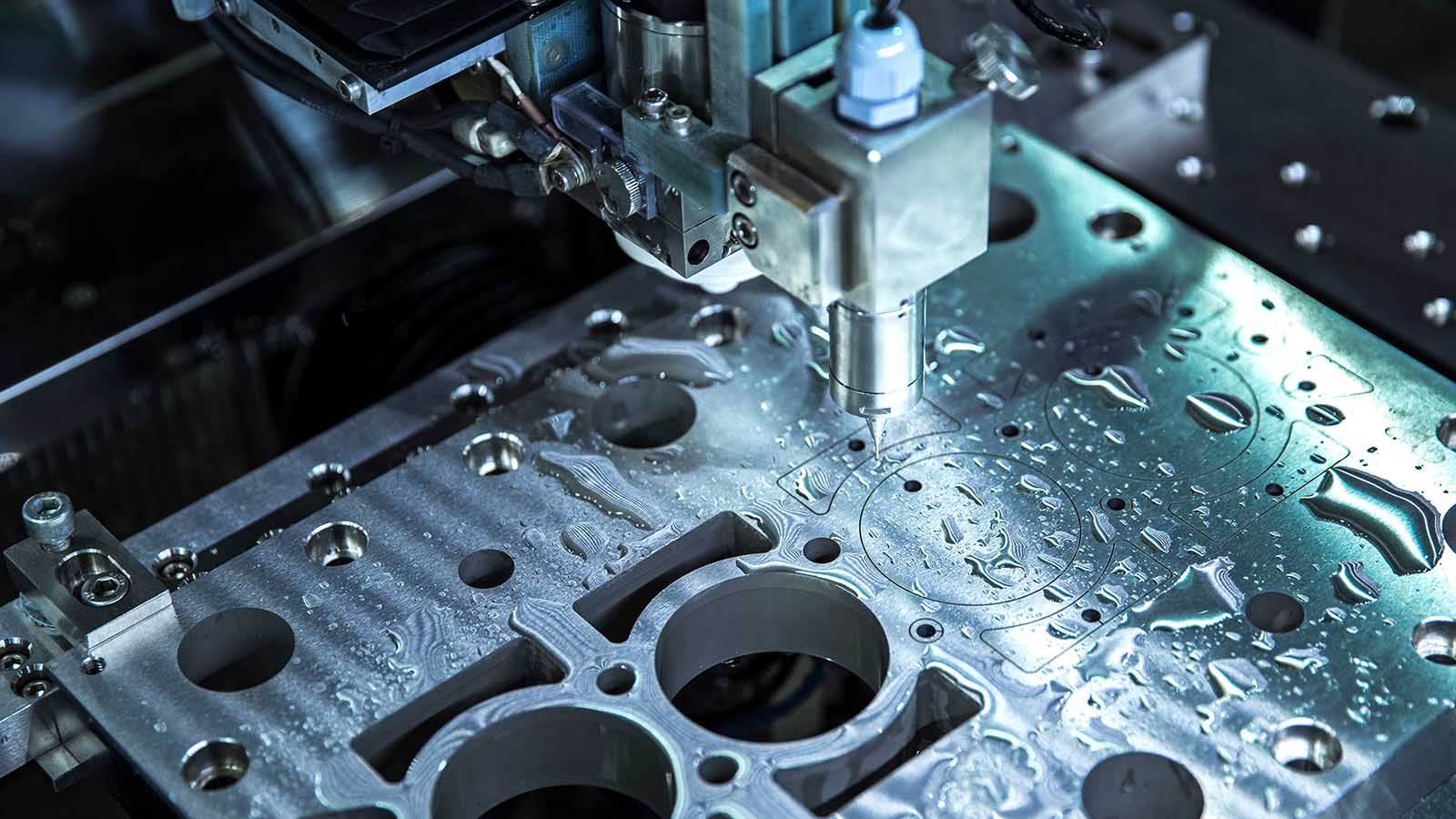

An industrial CNC router table is a computer-controlled cutting machine designed for large-scale production and intricate detailing. It automates the cutting process, improving efficiency, precision, and repeatability. These machines are widely used in industries such as woodworking, aerospace, metal fabrication, and signage.

Benefits of Using an Industrial CNC Router Table:

- High Precision and Accuracy: CNC routers follow programmed paths with extreme accuracy, ensuring consistent cuts and minimizing waste.

- Automation: Reduces the need for manual labor and speeds up production.

- Versatility: Handles various materials, including wood, aluminum, plastic, and composites.

- Scalability: Ideal for both small shops and large-scale manufacturing facilities.

The Role of ATC CNC Routers in Modern Manufacturing

An ATC (Automatic Tool Change) CNC router is a game-changer for industries that require multiple tool changes during production. Unlike standard CNC routers that require manual tool swapping, ATC CNC routers streamline the process, saving time and enhancing efficiency.

Advantages of ATC CNC Routers:

- Speed and Efficiency: Automatic tool changing eliminates manual intervention, reducing downtime and increasing productivity.

- Consistency in Production: Ensures uniform quality across multiple projects.

- Reduced Human Error: Minimizes mistakes caused by manual tool changes.

- Cost Savings: Less labor-intensive and reduces material waste.

ATC CNC routers are ideal for businesses that work with intricate designs and require frequent tool changes to handle different materials or cutting depths.

Exploring the Panther Series CNC Routers

For businesses looking for a robust and efficient CNC router, the Panther Series CNC routers are an excellent choice. Designed for high performance and reliability, these machines cater to both small and large-scale production needs.

Key Features of Panther Series CNC Routers:

- Powerful Cutting Capabilities: Equipped with high-speed spindles for smooth and precise cutting.

- Automatic Tool Changer (ATC) Option: Enhances efficiency by automatically swapping tools during operation.

- Durable Construction: Built with industrial-grade components for longevity and consistent performance.

- User-Friendly Interface: Intuitive controls make it easy for operators to manage cutting jobs effectively.

- Vacuum Table Option: Ensures strong material hold-down for precise cuts.

Why Choose Panther Series CNC Routers?

The Panther Series CNC routers are known for their reliability and efficiency. Whether you’re a small business looking to scale production or a large manufacturer aiming for precision and speed, these machines deliver outstanding performance. The ability to integrate ATC functionality further enhances their appeal, making them a cost-effective investment for any workshop.

Choosing the Right CNC Router for Your Business

When selecting an industrial CNC router table, several factors must be considered:

- Workload Requirements: Assess your production needs to determine the right machine size and power.

- Material Compatibility: Ensure the router can handle the materials you work with.

- Automation Needs: If your workflow requires frequent tool changes, an ATC CNC router is a must-have.

- Budget: Consider both the initial investment and long-term operational costs.

- Support and Training: Opt for a brand that offers excellent customer support and training to maximize your machine’s potential.

Conclusion

The rise of industrial CNC router tables has significantly transformed manufacturing and woodworking industries. Machines like ATC CNC routers enhance efficiency by automating tool changes, while the Panther Series CNC routers stand out for their precision, durability, and ease of use. Investing in a high-quality CNC router is a strategic move that can improve productivity, reduce waste, and increase profitability.

If you’re in the market for a CNC router that balances power and affordability, the Panther Series is an excellent option to consider. Whether you’re running a small shop or managing large-scale production, these machines will help take your manufacturing capabilities to the next level.