CNC routers have revolutionized modern manufacturing and craftsmanship, enabling precision cutting, engraving, and carving across various materials. Whether you’re a professional fabricator or a woodworking enthusiast, having the right CNC router for aluminum or woodworking can significantly improve your efficiency and precision. In this guide, we’ll explore how CNC routers for aluminum and CNC routers for woodworking differ, their benefits, and how to choose the best one for your needs.

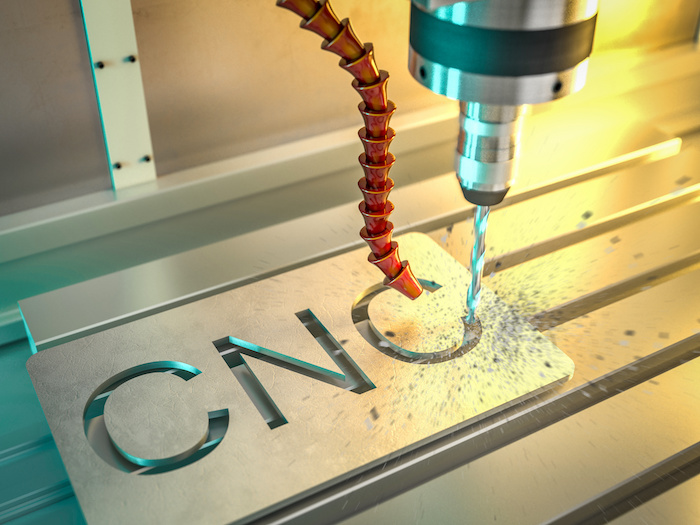

What is a CNC Router?

A CNC (Computer Numerical Control) router is a computer-driven cutting machine designed to cut, engrave, and shape different materials such as wood, aluminum, plastic, and composites. These machines operate with extreme precision, allowing users to automate the cutting process for both large-scale industrial applications and small-scale custom projects.

CNC Router for Aluminum: Features & Benefits

Aluminum is a durable yet malleable material commonly used in aerospace, automotive, and manufacturing industries. Cutting aluminum requires a high-performance CNC router designed specifically for metalworking.

Key Features of a CNC Router for Aluminum:

- Rigid Construction: CNC routers for aluminum are built with a sturdy frame, often made of cast iron or steel, to minimize vibrations.

- High-Speed Spindle: Aluminum cutting demands a powerful spindle with higher RPMs to achieve clean cuts.

- Lubrication & Cooling Systems: Unlike wood, aluminum generates heat during machining. CNC routers for aluminum are equipped with mist cooling or lubrication systems to prevent overheating.

- Precision Ball Screws & Linear Rails: These components ensure smooth and precise movement for detailed aluminum machining.

Benefits of Using a CNC Router for Aluminum:

- High Precision & Accuracy: Perfect for creating intricate designs and detailed engravings.

- Enhanced Efficiency: CNC automation reduces labor and production time.

- Versatility: Ideal for cutting, engraving, and drilling aluminum sheets for various applications.

- Improved Surface Finish: A high-quality CNC router prevents rough edges and ensures smooth finishing.

CNC Routers for Woodworking: Features & Advantages

Woodworking requires a CNC router that can handle various wood types, from softwoods like pine to dense hardwoods such as oak and maple. These machines are widely used for cabinetry, furniture making, signage, and artistic carvings.

Key Features of CNC Routers for Woodworking:

- Vacuum Table or Clamping System: Keeps the wood in place during cutting to prevent shifting.

- Powerful Spindle: Ensures smooth cuts across different wood types.

- Dust Collection System: Essential for keeping the workspace clean and safe.

- Custom Tooling Options: Allows for intricate carvings, engravings, and 3D relief work.

Benefits of CNC Routers for Woodworking:

- Consistent Quality: Eliminates human error for precise and repeatable designs.

- Faster Production Time: Enhances productivity for small businesses and large-scale manufacturing.

- Multi-Material Capability: Some CNC routers can work with plywood, MDF, and other composites.

- Customization & Creativity: Enables woodworkers to create unique and complex designs with ease.

How to Choose the Best CNC Router for Your Needs

When selecting a CNC router, consider the following factors:

- Material Type: Ensure the router is designed for your specific material (wood, aluminum, or both).

- Spindle Power: A higher-power spindle is necessary for metals, while woodworking routers require moderate power.

- Work Area Size: Choose a machine that fits your project dimensions.

- Software Compatibility: Ensure the CNC router works with your preferred CAD/CAM software.

- Budget & Brand Reputation: Investing in a reputable brand like Camaster ensures reliability and long-term performance.

Why Camaster is the Best Choice for CNC Routers

Camaster is a leading name in the CNC industry, offering high-quality, American-made CNC routers for aluminum and woodworking. Their machines are built for durability, precision, and ease of use, making them the go-to choice for professionals and hobbyists alike.

Why Choose Camaster CNC Routers?

- Superior Build Quality: Heavy-duty construction for stability and accuracy.

- User-Friendly Operation: Intuitive software and controls for beginners and experts.

- Customizable Options: Tailor your CNC router to your specific needs.

- Excellent Customer Support: Dedicated technical assistance and training.

Conclusion

Whether you need a CNC router for aluminum or CNC routers for woodworking, choosing the right machine is crucial for achieving high-quality results. Camaster offers top-tier CNC solutions that cater to both metal and wood cutting, ensuring efficiency, precision, and reliability. Invest in a Camaster CNC router today and take your craftsmanship to the next level!

Ready to upgrade your CNC machining capabilities? Explore Camaster’s CNC routers today and experience the best in performance and innovation!